| 7 Things You Didn't Know Ink Could Do |

| Written by David Eaves |

| Wednesday, 03 March 2010 19:09 |

|

We're all guilty of taking ink for granted. Yes, you can use it to leave a mark on a piece of paper, but it's capable of so much more. Below, we take a close look at seven extraordinary uses for ink. You'll be amazed by what a versatile substance it is. We explore ink that explodes, ink that glows in the dark, ink that's sticky and ink that could soon be used to save thousands of lives each year. After reading this, you'll never underestimate ink again. 1. Exploding Ink

Image credit: Pierre J Exploding ink is the stuff of childhood daydreams and James Bond films. Nevertheless, QinetiQ, a company with strong links to the British Ministry of Defence, has filed a patent to make it a reality. Produced from a cocktail of aluminum particles (1 micrometers in diameter), copper oxide particles (5 micrometers in diameter), epoxy varnish and alcohol, the ink is stable in liquid form, but dries to create an explosive fuse. The ink hasn't got the power to create a huge explosion itself, but can create a force sufficient to trigger the detonation of a bigger blast.2. Sticky Ink

Image credit: Joseph Gray Printing onto bottles in hot and humid countries has always been tricky. Condensation on glass greatly reduces print quality. Linx Printing Technologies have come up with a solution to the problem in the form of Linx Black versatile beverage ink 1058 and the Linx 4900BC continuous inkjet printer. This sticky ink adheres to bottles easily, penetrating condensation and staying put for as long as needed. The printer itself comes with an integrated printhead and air knife drying system which dries the print area on the bottle instantly prior to printing. What's more, the printer is able to achieve production line speeds of 6.25m/s.3. Bio-Ink

Image credit: Brucesflickr Organo are leaders in the highly experimental world of bioprinting. In association with Invatech, they have managed to produce a 3D bio printer which has the ability to print real human organs, cell by cell, using laser-calibrated print heads - this is printer ink on steroids! It's hoped that, in the not-to-distant future, these organs will prove of great value to patients awaiting organ transplants. Elsewhere, a company called Tengion has successfully printed bladders; Professor Nakamura of Osaka University has printed tissue tubes similar to human blood vessels; and Gabor Forgacs of the University of Missouri-Columbia has printed sheets of human heart cells.4. Glow-in-the-Dark Ink

Image credit: Archie McPhee Seattle We all know that glow-in-the-dark ink is available to buy in some stores, but few of us know how to make it ourselves (something which you definitely should NOT try at home!!) All you need is 1oz of cinnamon oil, 1/4oz of phosphorus, a bottle with a cap and a bowl. Simply combine the cinnamon oil and phosphorus in a small bottle with the cap on, place the bottle in a bowl covered with hot water and wait for the two to combine together.5. Nanoparticle Ink

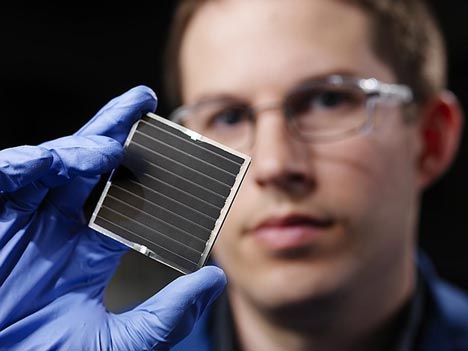

Image credit: PNNL Californian company, Nanosolar, uses nanoparticle ink to print high-performance solar cells, which convert sunlight into eco-friendly, renewable electricity. In the past, companies have produced these cells using a high vacuum manufacturing process, which is both slow and very costly. Nanosolar use a printer worth $1.65 million, which can print cells at a staggering 100ft per minute, 20 times faster and 10 times cheaper than the traditional manufacturing method. With their nanoparticle ink, Nanosolar can print CIGS (copper indium gallium selenide) solar cell semiconductor material onto long rolls of foil substrate.6. Invisible Ink

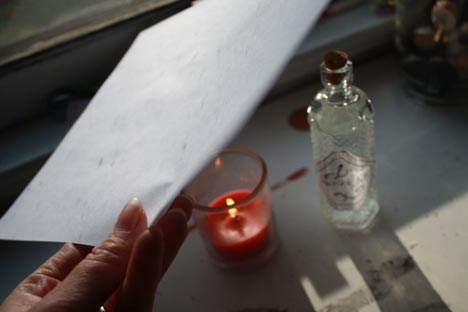

Image credit: gascoynebowman Like glow-in-the-dark ink, invisible ink is freely available to buy in stores, but you can make it yourself using lemon juice (exposed by heat) or vinegar (developed with red cabbage solution). The Stasi preferred to use cerium oxalate (developed with a solution of manganese sulfate, hydrogen peroxide and other chemicals), while during the Second World War, copper sulfate (developed with sodium iodide), iron sulfate (developed with sodium carbonate) and table salt (developed with silver nitrate) were commonly used.7. Sustainable Ink

Image credit: jimmedia The printing industry is hardly famed for its green credentials. Besides the vast amount of waste paper it produces each year, the inks it uses often contain heavy metals and VOCs (volatile inorganic compounds), as well as a non-renewable petroleum base. Seattle based printing company, The Big Print, are currently trialing a new type of eco-ink made from ethyl lactate, derived from corn, a renewable and abundant resource. If you really want to be green when printing at home, why not try the RITI printer, which prints using the leftover grounds from cups of coffee and tea, rather than traditional ink cartridges. |